CORVAIR EFI ENGINE CONTROL

As part of my project to convert a 1965 aircooled Corvair engine into an experimental aircraft engine, I have been working on building and setting up an engine control unit (ECU) to control the electronic fuel injection (EFI) and the ignition timing. This part of the project was as difficult and time consuming as the physical engine assembly.

MASTER CHECKLIST

I have made a master checklist of all items and actions needed during the engine conversion process. I've also included the EFI items and part numbers, it's all there:

Corvair Master ChecklistBOOKMARKS

MegaSquirt ECUHarley Davidson Throttle Body

Trigger Wheels

Ignition

Wiring

Software and Tuning

ENGINE CONTROL UNIT

The control computer is a MegaSquirt kit. I used the MegaSquirt II controller with the Version 3.0 control board.

Because the MegaSquirt ECU is an open source project (just a bunch of guys on the internet getting together to build these things) the ECU came as a kit. Also, to test the board I first had to build a Stimulator which was also a kit. The Stimulator provides user controlled engine signals to the control board so you can test the board and initially set up the control code.

The Stimulator is the first to get constructed. There are two variations of this Stimulator available, I got the more complex and more expensive one.

Stimulator complete.

And now I can start on the controller.

The partially complete controller and completed Stimulator are connected to each other for testing. Notice how this happens long before the majority of the components are installed on the controller. The steps are "install this, test it, install that, test it" and so on.

A few pictures of the completed controller. The whole project took a week or so of evenings to solder all the parts together. It was way too cold outside to do real work anyway.

MegaSquirt ECU complete.

ASSEMBLY NOTES AND SUGGESTIONS

There is going to be a lot of soldering of small components. This will be somewhat different than soldering wire together in your car stereo, primarily because the items are smaller, need to be grounded, and are sensitive to heat. I used a grounded 15 watt soldering iron; it doesn't have to be any bigger than this and it needs the ground plug. I also used standard electronics rosin core solder (60% tin / 40% lead) that was 0.032" diameter. This comes in 0.050" diameter, but this is a little large for micro-component work. To unsolder mistakes, I needed some de-soldering wick (its a fine copper wire braid that press between the bad solder and the iron and it sucks up the solder).

Since I have a newer computer, I had no serial port. I did use a cheap $20 USB-to-Serial adapter that, regardless of the name on the box, was a Prolific adapter.

The MegaSquirt can be configured for a variety of setups, so you have to know what equipment you plan to use (like injectors, if you plan to control timing and how, etc.) because there are a couple of different wiring options on the board. Here is what I plan on doing:

For engine speed, I will use a 36-1 missing tooth wheel with a VR sensor.I plan on using narrow band O2.

I initially plan on using the MAP sensor on the board.

My throttle body has a PWM idle valve and I installed the on-board components.

I will control the coil directly; I installed the high-current ignition circuit.

The injectors are high-impedance and I did not install the PWM flyback circuit.

CORVAIR-HARLEY THROTTLE BODY

Harley Davidson has been providing all of their motorcycles with fuel injection throttle bodies for several years. You can no longer get a factory Harley (or Honda, Yamaha, etc.) with a carburetor. This great thing about this is that there are those who will remove the fuel injection system to put a carburetor back on or upgrade the stock throttle body to one that is larger. This means that you can get what I got on EBAY for $99.

A Harley throttle body is sized for engines in the 100 horsepower range. This means that the intake and outlet diameters and the injector flow rates are all PERFECT for a Corvair.

Here's the cool part... look at the design: If you mount it under the Corvair engine and place it upside down, it already has two outlets that turn up a little. This is perfect for two intake runners routed up to the two sides of the engine. It also has a front flange ready for a Harley aftermarket air filter. So there will be no modification required for this body to bolt this to a typical Corvair conversion intake.

Here's a second really cool thing... all the sensors, injectors, and even a throttle cable attachment are included! From the pictures below, you will see (from right to left):

The flanged intakeThe throttle plate with return spring and cable mount

The throttle position sensor

The idle air valve

A hose fitting for a prime injection or a remote pressure sensor

The outside air temperature sensor

The manifold absolute pressure (MAP) sensor

Two injectors, one each side

The fuel connection tube

Two outlets

And the whole thing weight a pound or two

The only other sensors needed for a fuel injection system are the crankshaft position sensor (which will provide engine RPM) and the O2 sensor. Both of which are easy enough to find at AutoZone.

It's a bit difficult getting specifications for these sensors since Harley is really secret about their products (it forces you to go to a dealership). However, all of the sensors are Delphi and if you search the internet all week long, you can find what you need. I even found a source for appropriately priced connectors for the sensor fittings. If you look at my Master Checklist, I have the part sources and injector flow rates listed in the notes.

TRIGGER WHEELS

To generate an RPM input, I started using a 36-1 trigger wheel and a VR sensor. I had planned to put that on the rear of the engine. The Corvair harmonic balancer is about 6-3/4" diameter which means I need a pretty large wheel to stick out further than that. I've designed a few wheel templates and the file is here:

The design is based on using 1/8" (plus or minus) steel sheet, or just an old 10" table saw blade, and gluing the template on with spray adhesive (such as with 3M Super-77). The recipe: punch, pilot drill, and drill all the holes; rought cut the diameter down to size with a bandsaw; cut the teeth out with a band saw; finish the diameter with a lathe, and smooth off the burrs with a file.

I had a piece of 12 gauge sheet (0.105" thickness). In about an hour and a half, I had it roughed-out and this is what I had:

I plan to bolt it on using the pulley-puller bolt holes. I stacked washers so that the wheel stands off of the balancer a bit and to also keep the bolt threads from contacting the oil seal on the other side. The threads showing should be about 3/8"; at 1/2" you hit the oil seal. I will eventually replace the washers with stand-off ring.

OK, plans change...

I am now using the flexplate with slots cut in it for a trigger wheel. To the left at the 9 o'clock position you can see one spoke missing that will act as the "missing tooth". I calculated and drilled holes on the opposite side to keep things in balance.

Also, I didn't just cut out any tooth... I cut out the tooth that lines up with the #5-#6 rod journal. This way, I know where the damn thing is and I can index my propeller so that they are not lined up. Of course, I will use the settings in the software to adjust the timing (i.e. set the first spark to be some number of teeth or some degrees after the missing tooth; I couldn't be so lucky that that lined up too).

OK, plans change again...

When I tried to get it running, I had a real hard time getting the computer and the engine to sychronize with each other. With a missing tooth wheel, the software starts looking at teeth passing by and estimates a window of time when the next tooth is to be seen. If the next tooth isn't seen in that window, it is considered the Missing Tooth and it then knows where the crankshaft is. The problem I had, partly because I'm using a wimpy starter and partly because I have no large flywheel, is that I couldn't get a few smooth rotations to allow the computer to correctly see the missing tooth. The crank would slow down in spots and the computer would start falsely seeing "missing teeth" only because the actual teeth were late in the window of time. As oppposed to trying to get the missing tooth wheel to work, I just made it easier on myself:

I replaced the missing tooth wheel with a wheel with only three teeth. This is the same input that would be generated by electronic points running within a distributor. I then told the computer to forget trying to sychronize with a missing tooth wheel and just to spark when it sees a tooth. Well, actually it's not looking at teeth, but holes in the flywheel.

This is the wheel that I got the engine running on. It has only three holes and they and the sensor are lined up with 0 degrees TDC of each pair of pistons. Although I have to think about it, I can figure out where TDC of #5 and #6 are so I can index the prop.

I also made the holes so that the hole starts at TDC and ends at 20 degrees after TDC. Megasquirt allows you to choose between firing the spark during Cranking (not Running) either with an advance calculated from the tables OR based on when the input trigger "rises" or "falls". If I select "rises", it will fire the spark at TDC. "Falls" will fire it at 20 degrees retarded. I'll work through these options to see which works best.

One other thing about this arrangement. Since the computer doesn't sychronize with the crankshaft, it doesn't know which spark plugs are firing so it can't run a distributorless system (such as coil packs or coil-on-plug systems). I am using a distributor, but only the rotor and cap. The points, springs, weights, and vacuum advance were taken out. Well, more about that on the next topic...

IGNITION

The MegaSquirt ECU is used to energize and control the primary circuit of the ignition coil. Based on a detailed table, the ignition is timed based on RPM and manifold pressure. To keep things relatively simple, the ECU is asked only to provide three evenly spaced sparks for every crankshaft revolution (two crank turns for every cycle, six cylinders, you do the math). The distributor is used to send the sparks to the correct cylinder. Simple, eh?

On a Corvair, the distributor rotor points to the 9 o'clock position (straight left) when the #1 cylinder is at top dead center. Since I have the ECU controlling timing and there are no points, I can just bolt down the the distributor with the cap over the rotor in this position, right? Nope.

With the #1 terminal at the 9 o'clock position, the rotor and cap line up and would be perfect if I only planned to set my ignition at 0 degrees. Since timing is generally advanced, the distributor needs to be advanced a little (turned counterclockwise) so that the rotor and terminal are always in reach of each other to transfer the spark. In the picture below, my finger points to the #1 position. If I set the cap here and set timing to 60 degrees advanced, the spark would go to the #6 cylinder which is where my thumb is pointing to.

Knowing that my ignition will typically range from 0 to 30 degrees, I need to advance the cap about 15 degrees so that the cap and the rotor align in the middle of this range. Since the angle between the #1 and #6 terminal is 60 degrees, I turned the rotor so that #1 moves 1/4 of the way to the #6 position.

By the way, the firing order is 1-4-5-2-3-6 clockwise with the actual #1 cylinder adjacent to the distributor (seen in the picture above) and the #2 cylinder on the opposite side.

WIRING

The detailed wiring schematic is obviously available from the MegaSquirt website so I won't go into those details here. However, there are a few wiring details which are specific to this installation that you won't find anywhere. Interestingly enough, one of the most time consuming items on this whole engine build was figuring out which damn connectors to use! I probably at least spent a full week of eight hour days looking at manufacturer's parts drawings, websites, and Mouser.com to get where I am now.

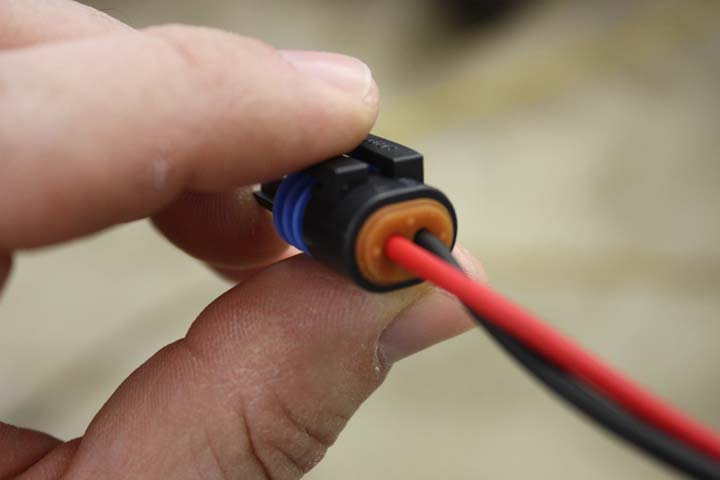

The majority of the connectors used on the sensors of the Harley trottle body are "Metri-Pack 150 series". Metri-Pack is a OEM standard (or it's a Delphi product that everyone copies) and the 150 means that the pin width is 1.50 mm in width. If you Google "Metri-Pack" you will get several distributors whose websites provide very detailed pictures. You can get several styles of the 150 series... all of the connectors used here are "sealed" (meaning a little rubber seal keeps water out) and most of them are "Pull to Seat".

The "Pull to Seat" is a style of pin design that locks the pin in the connector by pulling it backwards into the connector. So what you would do is feed the wires through the back rubber seal, then through the connector, then install the pins (crimp and/or solder), and then pull the wire and pin back into the connector where it lock into place. The rubber seal is then pushed in the back of the connector.

This style is generally used for sensors with an integral male connection; only the female "Pull to Seat" connectors are available as kits or as pigtails from supply houses. The throttle position sensor, intake air temperature sensor, oil temperature sensor, idle air valve, and my first VR sensor all had this style of connector. Commonly, the Pull to Seat style has an integral rubber seal on the back:

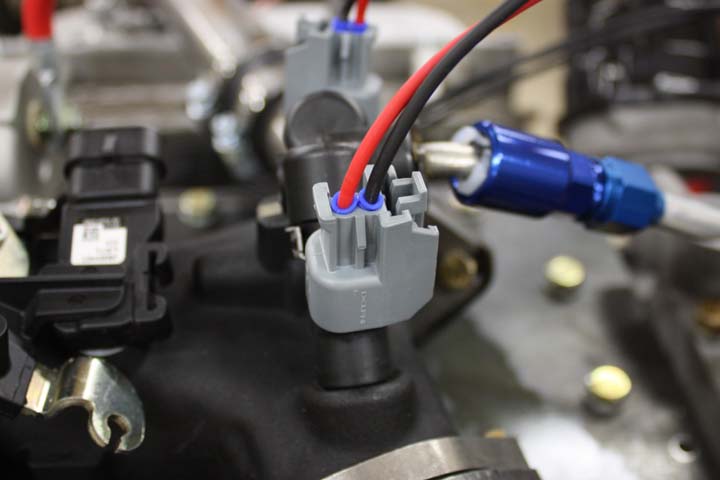

the other style of the Metri-Pack 150, which I guess is the standard connector, is notably different. The pins are the same size but a different style. And the wire seals do not come with the connector. But, the connectors are available in male and female versions so they are handy when you need to add a connector to a sensor the comes with unterminated wires (like the O2 sensors or the Hall sensor used for RPM).

You can see below the separate seals common to the Metri-Pack 150 series which are NOT Pull to Seat:

The final exception are the injectors, which are "Metri-Pack GT-150 series". Confused yet? I was. I'm sure there was some Delphi engineering manager that came up with all these styles just to keep his department in work!

the Metri-Pack 150 series is good for 14 amp continuous. MegaSquirt recommends 18 gauge wiring for everything; it's a little conservative but considering that some of the runs might be long, that's what I went with. I also made sure I ordered automotive accessory wire that was rated for engine compartments (Summit SXL)... I ordered a 100 foot roll of black and one of red and had plenty. I probably should have ordered a roll or blue for the sensors that have "power", "ground", and "signal".

You need to know your wire size when ordering the Metri-Pack connectors because there are different pins and seals available for different size wires. To make it worse, the pins and seals are cataloged for metric wire. A 18 gauge wire is about equal to a 0.75 mm2 metric wire (18 gauge is about 1.02 mm in diameter with a cross sectional area of about 0.8 mm2 and 6.6 ohms per 1000 feet of resistance). This information will be necessary for selecting the pins. The insulation diameter will be needed for selecting the wire seals.

I got all of my connectors from Mouser Electronics under Interconnects > Automotive Interconnects. It would be great if all the connectors were the same; the air intake temperature, the oil temperature, and my first VR sensor were all two pin... but were they the same Metri-Pack 150 Pull to Seat two pin connector?! Hell no. One had the catch on the side, one was upside down, what a pain in the ass. The nice thing about Mouser is they provide a picture of the part. And if that's not enough, they provide a link to the manfacturer's page for that connector. And if that's not enough, the manufacturer provides a link to the engineering drawing. So if your sensors and injectors are not the same as my sensors and injectors (of which part numbers are already found and listed in my Master Checklist)... GOOD LUCK!

Finally, the connector for the MegaSquirt is a typical DB-37 (DC-37, whatever) which are made for soldering 20 gauge wires to. Since a 18 gauge wire doesn't fit into a 20 gauge hole, I had to trim the wire a little. After I stripped the wire, I would snip the end at a sharp angle to create a point and this would fit into the pin hole a bit better. This also begs the question why we are using 18 gauge wire... A pin on the DB-37 is only rated for 5 amps and the actual pathway on the printed circuit board is even smaller yet, so 18 gauge seems overkill. Whatever.

OK, so this isn't wiring, but its a MegaSquirt connection... The standard manifold air pressure (MAP) sensor is located on the MegaSquirt board. You connect it to the manifold using some vacuum tubing, like can be seen in the picture below. I've simply brazed a piece of 1/8" tubing on to the intake runner. The Harley throttle body has a MAP sensor integral to the unit, but I have not used it.

SOFTWARE AND TUNING

As complicated as soldering several hundred tiny components on a board looks, it's not nearly as bad as getting the software right. The MegaSquirt guys have developed a pretty decent set of software tools. They have the primary control code that gets transferred or "burned" to the microcontroller on the ECU ("burned" is just slang for installing code on a microcontroller, no real damage is done). They have a nice little program that does this using a PC and a serial port. Then once the code is on the board, the ECU is essentially alive... but every setting has to be tailored to each unique installation. This is where it becomes difficult.

The current method for getting all of setting adjusted is to use the program MegaTune. This software from a user's point of view provides a nice interface to show some gauges on the screen, set settings from drop down menus, save your settings to a file, and has some wizards to develop some of the more complicated tables. From a programmers point of view, this package keeps one from having to modify the original written code, recompile the whole code, and re-burn the microcontroller. MegaTune knows where the variables are stored in the microcontroller memory and is capable of reading and modifying those specific addresses of memory while the controller and engine is running. Without this program, tuning would become ten times more difficult.

Below I have listed some of my INITIAL settings for reference. These reflect what I used to get the engine running on the test stand, but does not include any actual operational tuning. These will be changed, but I've listed them here so I can remember what the hell I did.

FUEL SET-UP

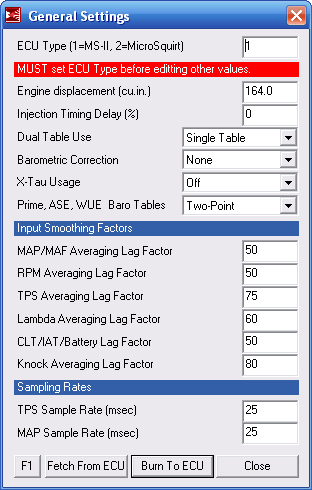

General:

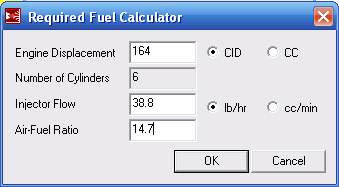

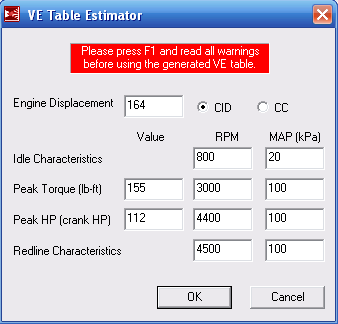

As you can see below, I stuck in 164 cubic inches which is the stock Covair displacement. However, with a 0.020" overbore the displacement is actually 166 cubic inches.

Idle Control: none

Spare Port Settings: all disabled

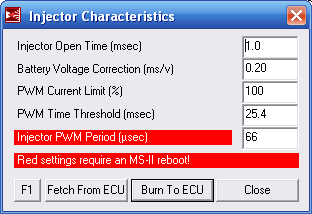

Injector Characteristics:

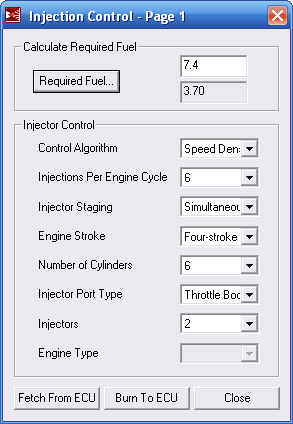

Injector Control:

The MegaSquirt online manual does not due justice how important these specific settings are. And although I've avoided rewriting their manual on my web page, I will go into a little more detail on this screen. Until I understood how all these settings affected each other, I was a bit lost.

The Required Fuel (shown here as 7.4) is how long in milliseconds a single injector serving a single cylinder should stay open for one intake stroke given 100% volumetric efficiency. In other words, this simply indicates how much fuel is required for one cylinder for one cycle based on the size of the cylinder and the flow rate of the injector. This number is the basis of which the VE table uses to generate a duty cycle. If the table's duty cycle states that 75% is needed for a given RPM and manifold pressure, the actual injector opening time is 75% of this Required Fuel.

The Required Fuel in the grayed out box (shown here as 3.7) is the value the computer actually uses for every crank rotation. So why should this be different from the first value of 7.4? For starters, I don't have one injector for each cylinder, on the throttle body I have two injectors for six cylinders. Also, since this is a four stroke engine, I only fill half of those cylinders each crank rotation. Additionally, as opposed to one big squirt for each crank rotation, I'm asking for three (which is six per cycle as shown on the screen). So...

Two injectors doing the work of one changes Required Fuel from 7.4ms to 3.7ms ( 7.4 / 2 )Six cylinders as opposed to one changes Required Fuel 3.7ms to 22.2ms ( (7.4/2) * 6 )

Only filling half of those cylinder every crank rotation changes 22.2ms to 11.1ms ( ((7.4/2)*6) / 2 )

And breaking that one squirt down into three per rotation changes 11.1ms to 3.7ms ( (((7.4/2)*6)/2) / 3 )

A couple of things to note: I could have changed injections per cycle to a lower number and still may. The MegaSquirt manual has more information how higher and lower numbers come into play. The other real important factor is changing the Required Fuel base number to globally tune the engine. To give an example, if you are running lean, there are three ways to richen the mixture. (1) you could increase every number in the VE table, (2) you could increase the fuel regulator to a higher pressure, (3) you could increase the Required Fuel number.

I showed 7.4ms here, but with a 166 cubic inch engine (0.020" overbore) I get 7.5ms. To get the thing running the very first few times, I plugged in 10, 15, 20, and 25ms. At 25ms it was so rich it was blowing black smoke! So the plan is to find a Required Fuel setting and a fuel regulator pressure setting that work generally well, and then fine tune with the VE table.

And one other real important item... at 5000 rpm, one crankshaft rotation happens in 12ms. With these injectors opening 3.7ms three times per rotation, that totals 11.1ms. Now, the volumetric efficiency won't be 100% at 5000 rpm (and the resulting fractional duty cycle will open them less than 11.1ms), but that points out the fact that I can't simply take my 7.4ms setting and change it to 10ms, 15ms, or 20ms successfully. There simply would not be enough time at higher rpms to open the injectors as needed. If running lean and you can't increase the Required Fuel setting any higher, the only other options are to increase the fuel pressure or change the injectors to ones with a higher flow rating.

And this is the calculator that I used to get 7.4ms in the first place:

Rev Limiter: none

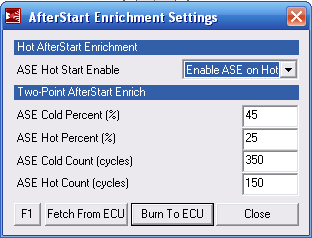

AfterStart Enrichment:

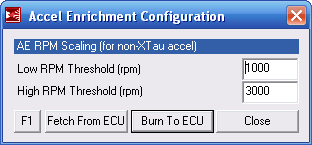

Accel Enrichment Config:

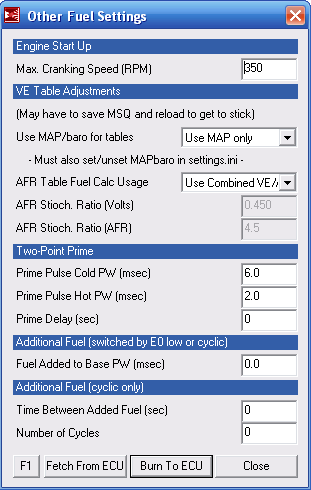

Other Fuel Settings:

2-Point Barometric Correction: not used

Flex Fuel: not used

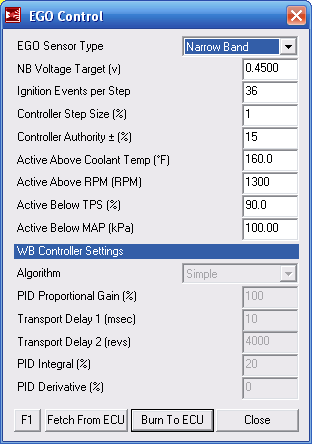

EGO Control:

The below settings control where the O2 sensors does its thing. I was initially concerned with the code's ability to provide closed loop operation for our application since we operate at 75% to 100% power; this is where a normal ECU would go into open loop and turn off O2 correction. However, you can see that I put the Active Below TPS at 90% (90% open throttle) and the Active Below MAP at 100kPa (100kPa is about atmospheric so unless you go turbocharged MAP will always be below this setting).

There was some discussion on the internet about running lean of peak during normal flight. One potential way to do that would be set the Narrow Band O2 voltage target from something other than 0.45 volts at a point where it runs lean (actually, normal operation of an O2 sensor is right on the rich edge of "economy" and you could just leave it there). The VE table would be set rich, the Automatic Mixture Control would be kept off (so the O2 correction doesn't change the VE table), and the Active Above RPM would be set higher than what I show (maybe 2200). When your throttle is open more than 90%, it runs open loop off of the rich VE table for "power". Pull the throttle back below 90% and it starts leaning per the O2 setting. Pull the throttle back some more (as in a descent) and it goes back to the rich open loop.

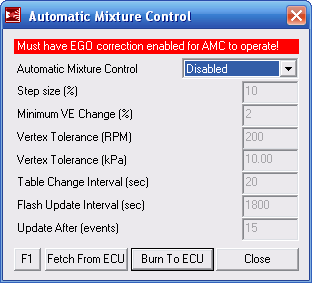

Automatic Mixture Control:

This was initially turned off, but will turn it back on with FLASH Update and with the disabled settings shown to allow the computer to adjust the VE table. I just didn't want the Stimulator to initially modify the settings.

Alpha-N Blending: not used

MAP vrs MAF usage: No MAF (mass airflow device)

IGNITION SET-UP

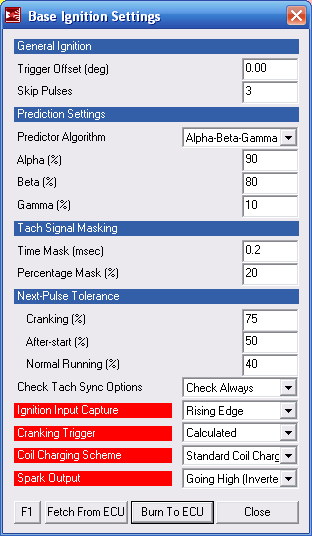

Base Ignition Settings:

It shows skip pulses to be 3, but I think I lowered that even more. This is how may initial pulses it skips before "sending calculated ignition signals" which either means it's not sending them at all or is sending them without advance corrections from the tables. I couldn't figure that out (and I didn't ask).

I'm using a Hall effect sensor that watches a hole in the flexplate. I've also wired my MegaSquirt so that this sensor grounds and completes the optical input circuit. So, when the Hall sensor is in front of the metal flexplate, the optical circuit is energized high. When a hole passes by, the circuit goes low. Which means, if I wanted to catch the front edge of my hole the Ignition Capture should probably be "Falling Edge". It runs now, but the ignition is probably 20 degrees retarded (which is the difference between the front edge and back edge of the hole). Just something I need to check.

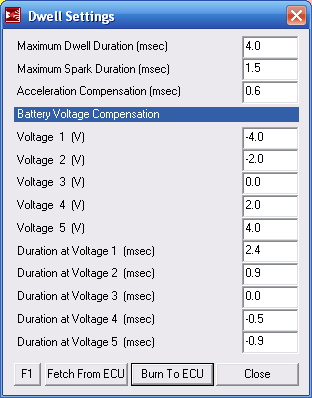

Dwell Settings:

The 4.0ms dwell time is probably a little high. I think the spark is so strong with this setting that it's shorting through the spark plug wires where a couple of them touch metal. Now that I have it running, I'll lower this number until the spark is too weak to smooth run the engine and then turn it up a little from there.

At 5000 rpm, the crank rotates in 12ms and there are three sparks in that rotation. This means there is 4ms for coil to charge, discharge, and start again at that rpm. This consideration must be taken when setting Maximum Spark Duration.

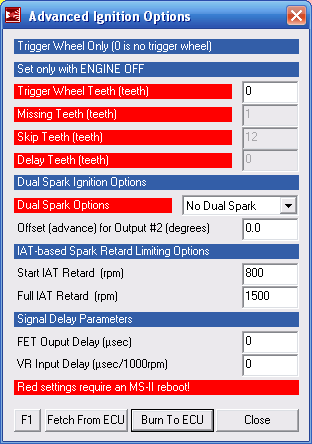

Advanced Ignition Options:

See that big-ol' zero in the Trigger Wheel Teeth setting? That shuts off all the missing tooth calculations. At one time that was set to 36 and I had a 36-1 wheel installed, but could not get that sucker to work. Now that I have a different starter and maybe after I get all the other settings tuned up, I'll try the 36-1 wheel again (I may consider a distributorless ignition system that would require it). But my three tooth wheel works just fine with the gutted distributor I have now.

Knock Threshold: not used

BASIC TABLES

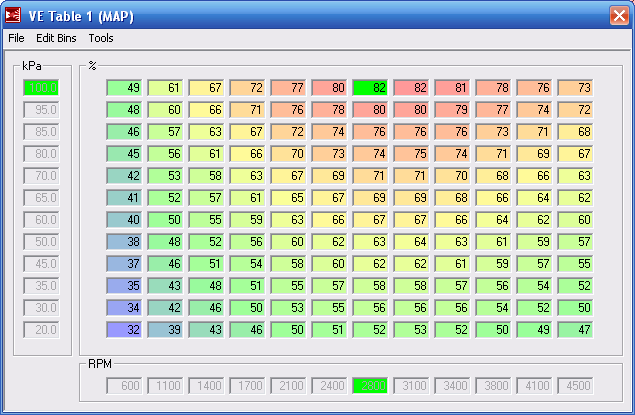

VE Table 1:

I used the Generate Table choice under Tools of the table window to initially fill my Volumetric Efficiency (VE) table.

This created the following table.

When I first got it running, the Required Fuel of 7.4ms was much too low, so I turned it up until the engine ran (almost doubled it at first). This could mean a few things. (1) my fuel regulator setting is way off, (2) my injectors are not 38.8 lbs/hr but actually lower, (3) or my engine gulps more air and has a higher HP and torque rating than I used in the VE Table Estimator.

I'm pretty sure the injectors and regulator are correct and those are easy enough to double check. The HP and torque numbers I got from the original GM data sheet on the stock engine. But since my engine doesn't have the same intake, the same exhaust, or a muffler it is likely that more air flows through this than the stock model. Consequently, it will have a higher HP and torque rating. Sweet.

ARF Table 1: not used

VE Table 2: not used

ARF Table 2: not used

Spark Advance Table:

I studied the curves of several different EFI systems and found that they typically followed a pattern. At the lowest MAP (throttle closed, 0 kPa), the timing advances linearly to about 2/3 of the maximum RPM and then levels off. At the highest MAP (wide open throttle and a little ram air, 110 kPa), the timing advances a little quicker following a curve, reaches its max about 1/2 of the maximum RPM, but doesn't go as high as the lowest MAP values.

So using GRAPH PAPER, I replicated the two curves that I had been seeing (one curve for closed throttle and one for wide open throttle).

I started with 5 degrees at 600 RPM at both MAP values. At closed throttle I reached a maximum advance of 20 degrees at about 3600 RPM. At wide open throttle I reached a maximum of 15 degrees at about 2400 RPM. Using the nice curves drawn on the graph paper gave me smooth changes at all the incremental RPM settings. I just interpolated between the curves for values at all other MAP settings.

But when I initially tried to start it up, I had a couple of kickbacks. To make things a little safer, I simply selected the entire table with the mouse, a little math bar popped up, and I took 5 degrees out of the whole table. This put my low settings at TDC (zero degrees). When I want to add advance, I'll just select the whole table and multiply it by some number (like 1.5); this will keep the low settings at 0 and raise everything else 50%. Cool.

OTHER TABLES

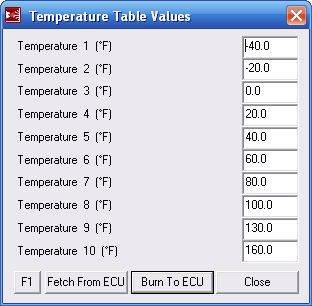

Temperature Table Values:

The following tables are not used, which isn't to say that their function isn't being employed by a simpler single variable set somewhere else.

Alpha-N MAP Table: not used

Barometric Correction: not used

Priming Pulse: not used

Cranking Pulse: not used

ASE Percentage: not used

ASE Taper: not used

TUNING, X-TAU TUNING, OTHER TUNING

Most of the remaining tuning fuctions will require the engine to be completed and will help modify the VE and other tables and settings. However, there are a few worth checking into:

Warmup Enrichment in provided and is based on water temperature. In a Corvair engine there is no water. You either have to watch the case temperature, the oil temperature, or disable Warmup Enrichment. I will be using the oil temperature (the computer will think its the water temperature) and just left the enrichment settings at default. Obviously, water temperature and oil temperature will have different values for a "warm" and operating engine so I will have to adjust the setting when I get some experience on typical oil temperatures.

The Acceleration Enrichment for our engine MAY be different as well. In a car, you can put it in neutral and rev the engine very quickly. In an airplane, there will always be this large flywheel mass (the propeller) and the acceleration won't be as great. So either the enrichment will need to be set for a slower acceleration that the defaults, or it won't matter anyway.