CNC ROUTER INFORMATION

GENERAL INFORMATION - WHITE PAPERS

Shopping for or building a CNC router is no easy task. To ease this process, I wanted to put together some basic information on the topic. Regardless of what company or machine you go with, please consider reading the following. These sections were written to provide a better understanding of what appears, at first, to be a very complex system. In fact, it is a unique combination of very simple systems which are common to all CNC's, from the entry level to the most expensive machines. I hope that your find the following information useful.

- Don't even know what CNC stands for? Please read... The Basics of a CNC.

- Buying a CNC? Building a CNC from scratch? Please read... Construction of a CNC.

- The salesman just showed me a really fast CNC! Please read... Speed, Resolution, and Accuracy.

- Yep, I've been burned by buying the wrong CAM software... CAM - Keep it Simple Stupid.

HAINES CNC ROUTER PLANS

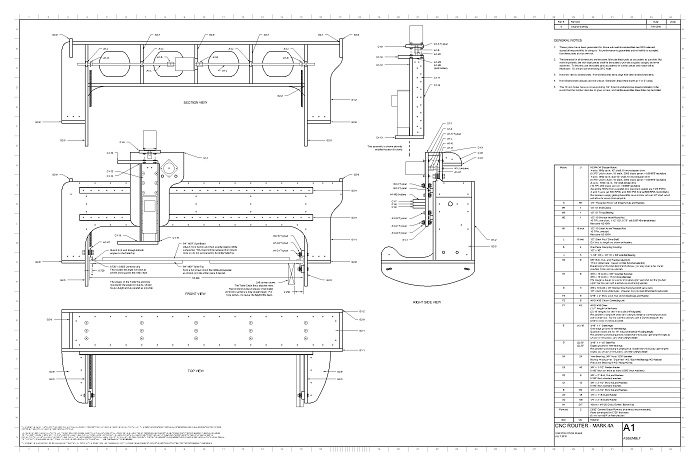

The computer numerically controlled (CNC) router shown on these pages reflects the result from several design iterations, with the goal being a CNC router that is inexpensive, can be built by a do-it-yourself (DIY) hobbyiest, and is stout enough to be used in a modest production environment.

My previous CNC routers were of steel and aluminum construction; these were great designs but required metal working tools, something not found in the typical woodworking shop. So my current CNC design utilizes plywood construction. It is just as rigid as previous designs, but can be fabricated in a woodworking shop. And, if you are lucky enough to already own or have access to a CNC router, the parts in this design can easily be cut from a typical 2-1/2 or 3 axis CNC.

- With 900 oz-inch (plus or minus) NEMA-34 stepper motors, you can expect 600 inch per minute (ipm) rapid movement and no problems rough cutting 3/4" plywood at 100-150 ipm.

- The cutting area is 50 inches wide with the length as long as practical. Currently, we are running a 16' long unit that has a cutting length of 14'.

- The y-axis uses a shaft to connect the left and right gantry drive sprockets so only one motor is needed... and once adjusted this keeps it from racking out of alignment when the power is turned off.

- The bearings are vee-bearings riding on ground angle iron and flat steel stock (we ground ours with a bench grinder in a plywood jig).

There is a free set of plans available for download. However, please respect the fact that you are getting these plans for free. In other words, please don't email with lots of questions during your build. And, there is absolutely no warranty, guarantee, or acceptance of liability by the provider of these plans. You are completely on your own.

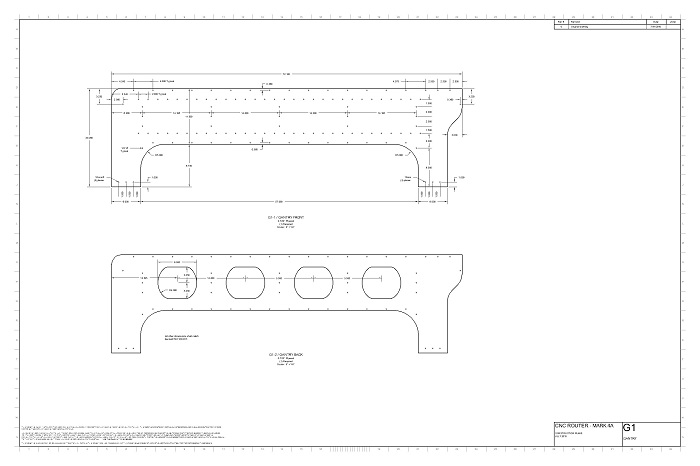

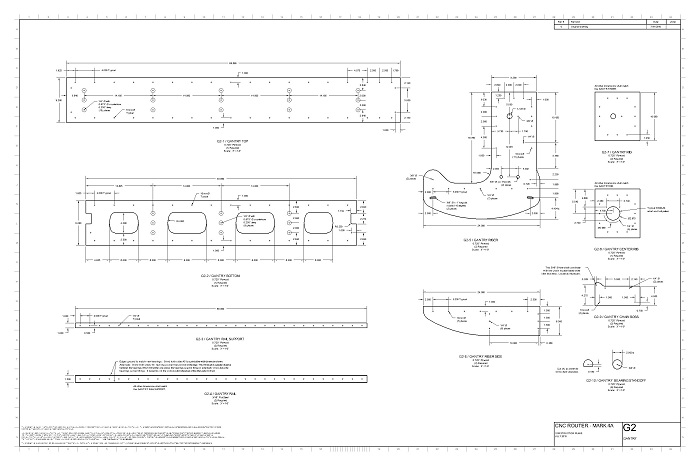

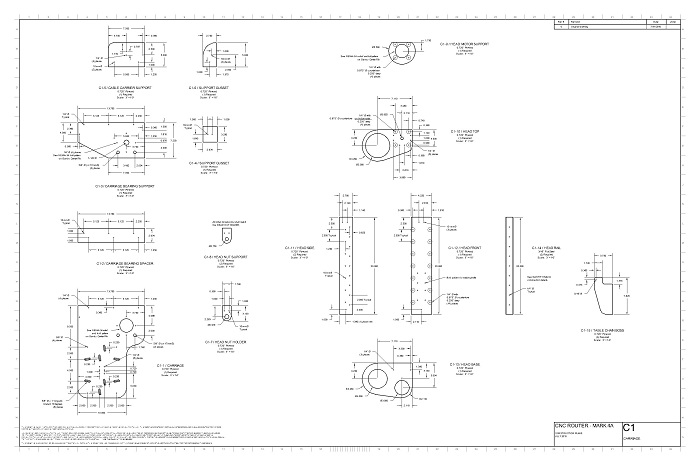

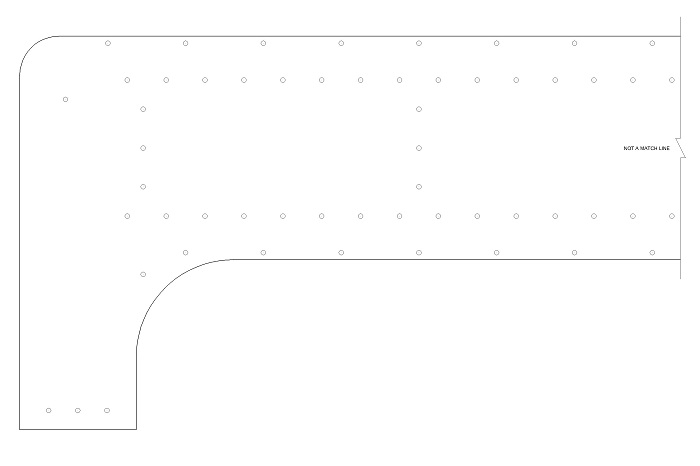

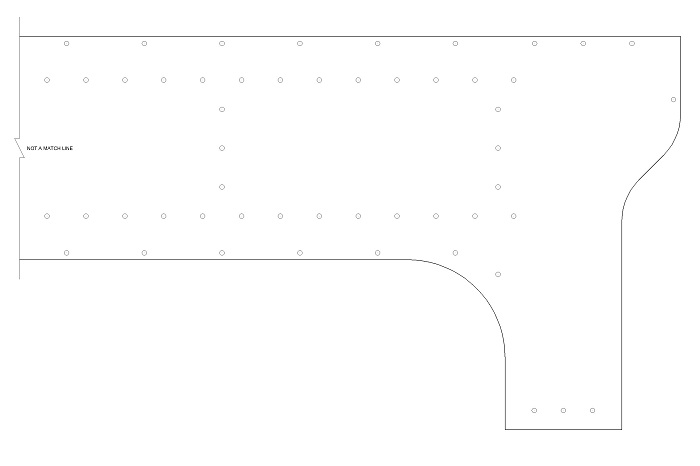

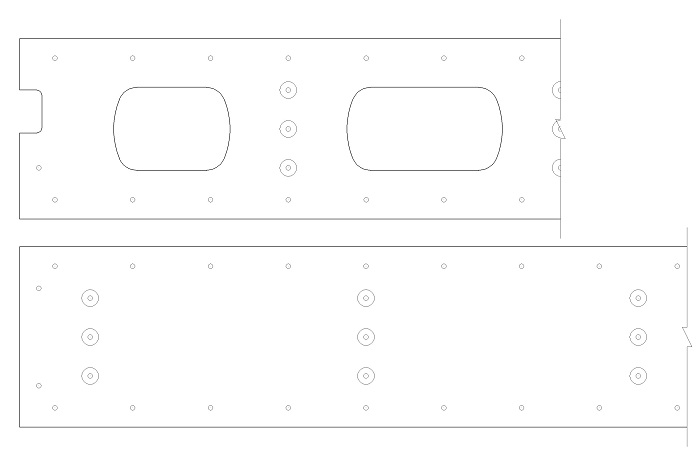

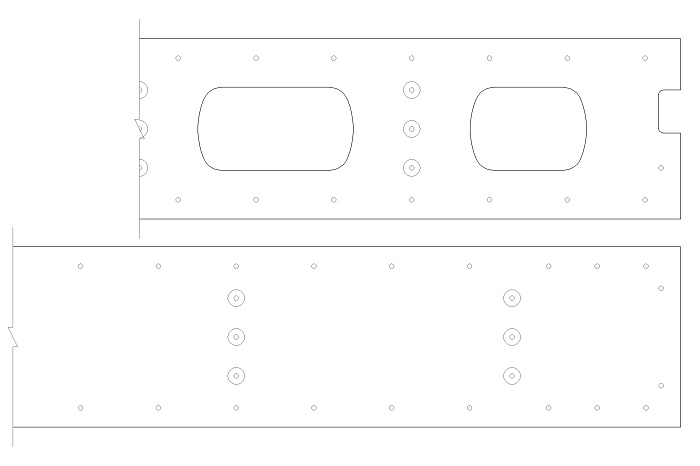

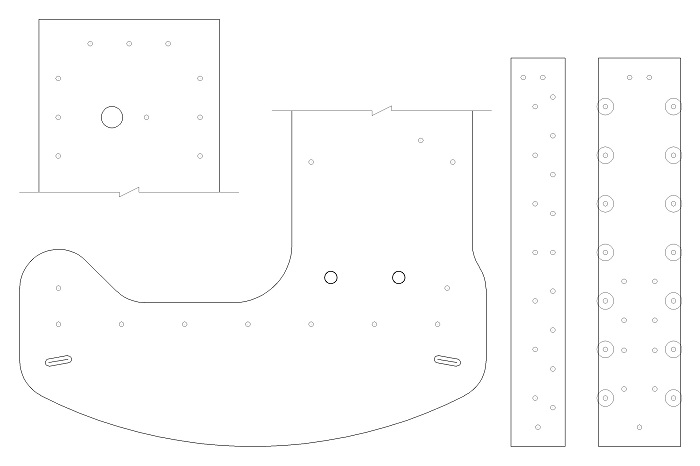

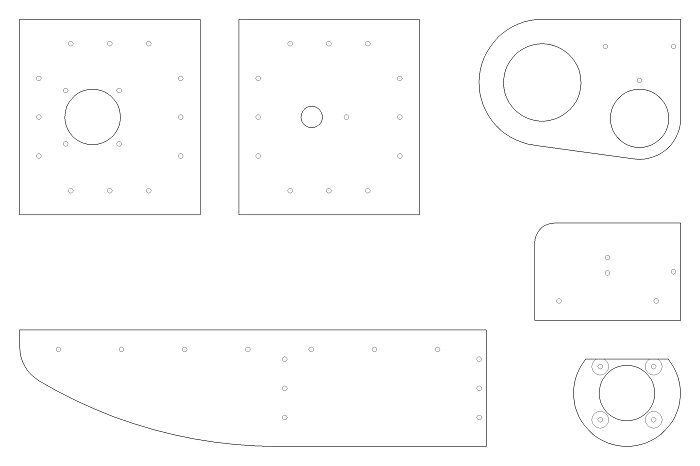

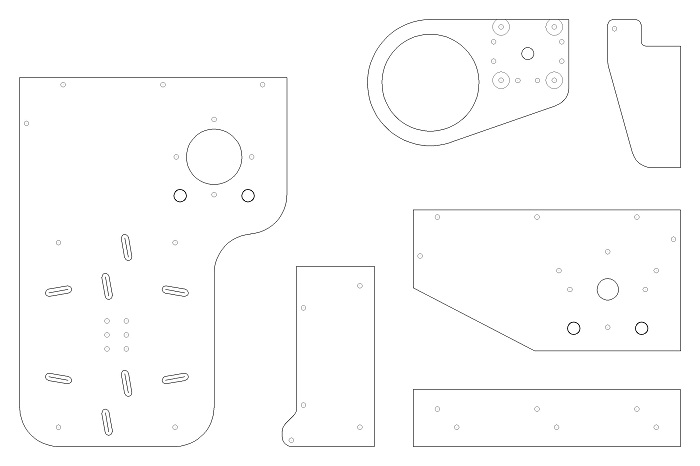

The following images show what is provided in the plans set.